Sioen is set on technicity.

Our fabrics and membranes for biogas installations have excellent specs and withstand exposure to numerous severe conditions that could permanently damage the fabric. Sioen membranes show outstanding performance and technicity thanks to the dedicated engineering.

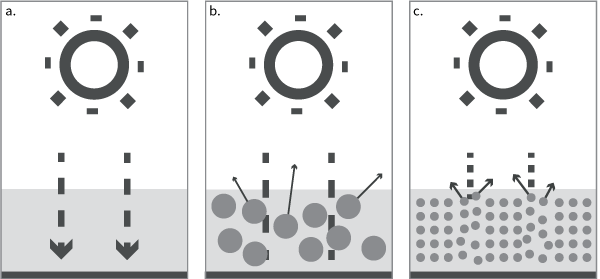

Topcoats

Our top coats provide good cleanability, good processing and they are an efficient barrier for plasticizer migration and weather impact. They are a balanced compromise between optimised weldability, excellent resistance and durability, among others.

This innovative generation of patented top coats was created by our 200-headed R&D department in cooperation with the Sioen Chemicals Division.

All our membranes are directly weldable without preparation, which guarantees perfect seams. In addition, our low wick treatment contributes to maintain robust seams throughout the structure’s life time.

Thanks to our unique lacquer, our membranes have excellent resistance to biomass and biogas and durable easy cleaning properties.

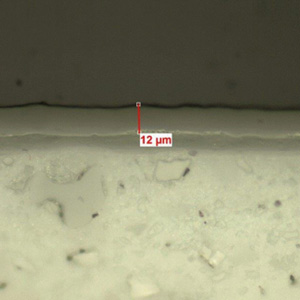

Low wick

Thanks to our membranes’ low wick properties, the mechanical and aesthetical properties are preserved. Wicking is the migration of moisture between the filaments of the fabric. It occurs when the woven base fabric is directly exposed to extreme humidity and it can result in fungal and bacterial growth.

The phenomenon initially results in an aesthetical appearance that looks poorly, as yellowish, brown lines and stains appear all over the base fabric and at the seams. In very bad cases, the physical performance of the fabric decreases and might lead to structure failure.

Fortunately, Sioen membranes undergo our in-house low wick anticapillary treatment, which prevents wicking. The treatment successfully avoids all water, dirt and fungus absorption inside the fabric and ensures long lasting aesthetics, minimal discoloration and uniform translucency.

Flame retardant

All biogas materials should comply with the local and international safety regulations. One of the most important properties is the ability of the membrane to avoid fire initiation and propagation over the structure.

All biogas fabrics are produced using high quality flame retardant additives in order to achieve appropriate flame retardant performances recommended by the biogas industry. Our materials meet the required specifications, as they are self-extinguishing, they have low flame propagation and have no flaming droplets.

The ability of a fabric to burn or ignite, causing fire or combustion, is quantified in fire standards. Internationally, there is a variety of test protocols to evaluate the flammability of a textile material. All Sioen membranes comply with the following fire standards: DIN 4102; EN 13501-1; NF P92-507; BS 7837 and with the California Code of Regulations.

Temperature resistant

Our Sioen membranes are sold and used in structures all over the world. That also means that they are used in many different circumstances.

Luckily, our biogas membranes have a temperature resistance ranging from -30°C to +70°C. The material remains flexible, even at a low temperature. That way, it can be easily handled and installed.