Unique cutting-edge production

Sioen is a production company. The founders built the company from the ground up and their successors were born amidst machines, so as to say. Producing better and more efficiently than anyone else was and still is one of the grassroots of the company. The love for technology, the care for machines, the high level engineering and the sophisticated skills push us forward, resulting in the best membranes for biogas installations.

12-position direct coating method

Our ranges Master, Tras and Expert are produced on technology driven direct coating lines with a unique 12-position method.

Every step of our production process is carefully monitored by the machine itself. Yes, we use artificial intelligence. Our machines are equipped with the best technology. It is complemented with the machine operators’ visual monitoring. Team leaders and production managers have instant data on productivity, quality, speed, … and any abnormality is immediately detected and solved.

Robots are moving the barrels with PVC paste on and off the line. We produce all pastes ourselves in our ”kitchen”, using home-made pigment pastes.

1. Flattening station – controlled kick-off

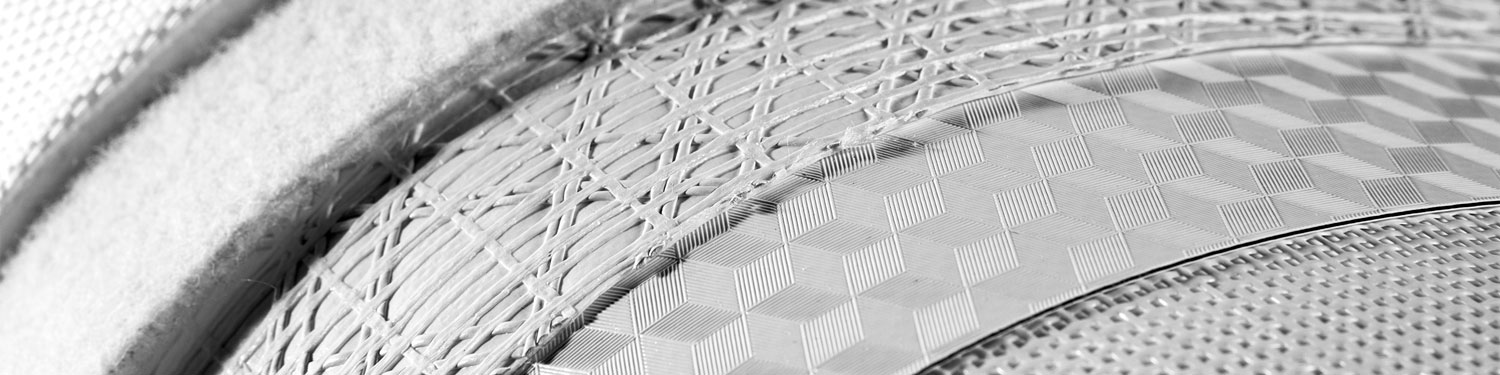

The home-made polyester fabric is pre-treated at the flattening station, where hot rolls set the basis for the stability of the final tensile architecture membrane: shrinkage is controlled and the fabric is flattened.

2. Base layer 1 – PVC paste entering the pores

The first step ensures that the paste enters deeply into the pores of the fabric. This second step, when applying the special base-layer mixture paste directly onto the fabric and curing afterwards, makes sure both paste and fabric are bonded together for life.

3. Top layer 1 – PVC paste aesthetics

The base layer and fabric that are tightly cured now, are covered with a top layer. Weight balance on the entire width of the fabric is highly important and monitored throughout. The first 2 layers are the back of the fabric. In tensile architecture this is the side you see from the inside.

4. Flip station – stable conditions

By coating back and front on the same machine and in line, conditions are kept stable and this in turn increases quality levels of your biogas membrane. Conditions in regard of mechanics, for instance the heat of the ovens, speed, operators, but also the same paste formulations from the same batches are “invisible” criteria that make sure you have the best quality coated fabric for your hall, sunshade or tensioned structure.

5. Base layer 2 – impregnated paste all the way round

Because of the flattened fabric, the paste is better impregnated into the fabric, covering the flattened yarns all the way around, preventing delamination.

6. Top layer 2 – layered to perfection

With a carefully set weight balance, the fabric is held between clamps on both sides. This top layer with special formulation paste is monitored to the finest detail. It is the layer that will be seen from the top and that is exposed to all weather conditions. It goes without saying that this is a crucial element of your membrane.

7. Varnish layer 1 – backside primer

The back of the fabric has an extra surface treatment on this machine position. This plays an important part in the weldability of the fabric and in the final visual aspect of your biogas structure.

8. Varnish layer 2 – frontside primer

The front of the membrane has a primer. This is a special biogas varnish for extra protection of the coated membrane.

9. Varnish layer 3 – Surface treatment for excellence

This final surface treatment is the finishing touch of the membrane. Special formulation of the varnish and a unique application through dip coating ensures a perfect visual aspect and an outstanding resistance.

10. Rolling station – defining the final aspect

Contrary to what one might think, the absence or presence of a varnish does not make it per definition mat (dull) or shiny. The final treatment with special rolls, cylinders or calenders contributes to how a membrane for tensile architecture will look like. Depending on the application and the type of product this could be extremely dull, with a great shine, regular dull or shiny and even with a leather look or with a 3D cube embossing for certain applications.

11. Visual inspection – human and camera inspection

Before roll-up, the membrane is carefully inspected by both cameras as well as operators, making sure your membrane is fit for use in your design.

12. Packaging – smart in line packaging

In line packaging prevents unnecessary contamination, the roll has not touched the floor on any moment and is ready to be shipped.